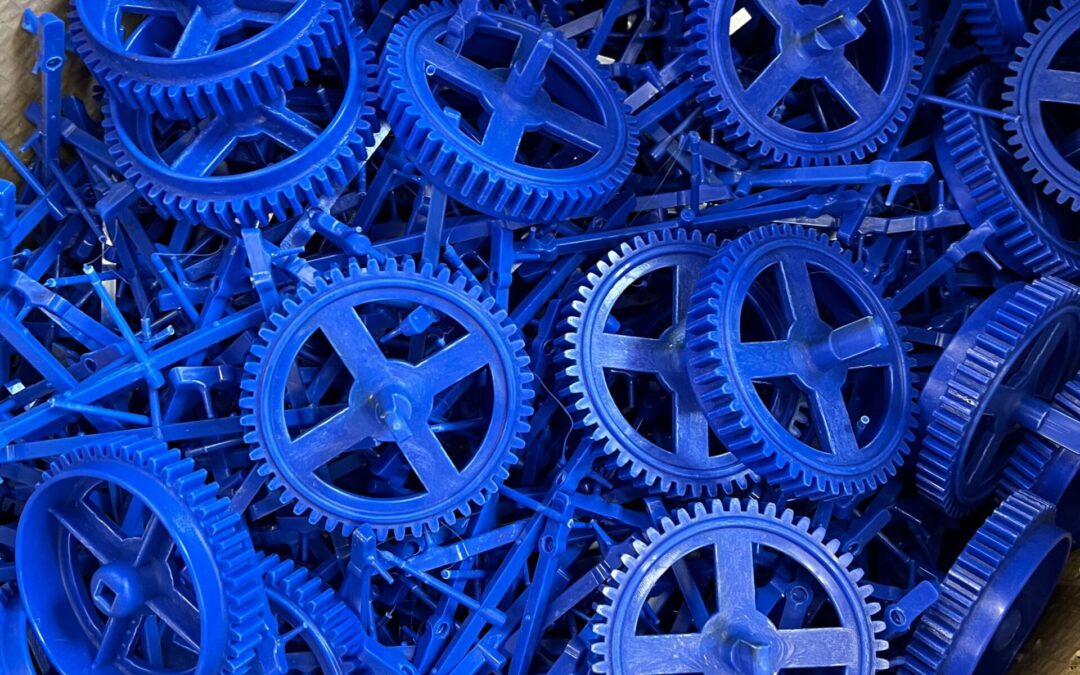

Plastic injection moulding is an advanced manufacturing technology that has dominated several major industries, including the automotive and heating sectors. However, the plastic injection moulding materials vary depending on the requirements of the application. So, plastic injection moulders, such as ourselves, strive to utilise only the most optimally-performing materials available on the market.

The same level of care and precision is applied to the materials we use in our automotive refinishing products. We understand that the quality of the material used directly impacts the performance and longevity of the final product, which is why we source only the highest-quality materials for our automotive refinishing products to ensure they meet and exceed industry standards.

These materials span across thermoplastics such as Polypropylene and polyamide plastics such as Nylon. All of which hold exquisite properties such as immaculate tensile strength and durability. Therefore, they immediately optimise an application, offering a longer lifespan.

Related: Plastic Injection Moulding Defects

What materials do we use at Plastic Supplies Dudley?

Below we have outlined some of our most popular materials so that you can get a better understanding of which would suit your needs the most.

Polypropylene

First, on our menu of plastic injection moulding materials, we have Polypropylene. This material is a polymer that is produced by combining several propylene monomers. It is most commonly used in the automotive industry, consumer goods packaging and textiles. For instance, Polypropylene is excellent for bumper and wheel cover production, as well as strapping tape and flat bags.

Nylon

Plastic injection moulding companies rely heavily on Nylon for its toughness and resistance to extreme temperatures and chemicals. The term Nylon refers to a group of polyamides which hold many materials such as Nylon 12 and Nylon 6. Due to its wide-ranging materials, Nylon holds an abundance of properties, including the most common which is the absorption of moisture which heightens the flexibility and durability of the item.

Acetal

Acetal is a plastic injection moulding material that is much more sturdy and robust than others. Often used for general purposes, this is a thermoplastic that has little surface friction or flexibility. Therefore, it is able to hold its structural integrity, even when in contact with intense thermal and weather conditions.

ABS

Last but not least, we have ABS. Also known as Acrylonitrile Butadiene Styrene, ABS is one of our most versatile materials available. It can withstand high impacts and general wear, making it ideal for electronics. Also hugely used in 3D printing, ABS has a low melting point, allowing for easy manipulation and recyclability.

Plastic Injection Moulding from PSD

Plastic Supplies Dudley is one of the most prominent plastic injection moulders in the West Midlands. Using only the finest materials, we continuously deliver immaculate products that are intricately designed and manufactured to meet their purpose.

Our bespoke service has held success through prioritising attention to detail, as well as our commitment to the exceptional service that we provide our customers. Because of this, our plastic injection moulding services are second to none for their fast turnaround time and affordability.

We pride ourselves in offering a streamlined service that has allowed us to sustain partnerships with some of the biggest names today. For more information on our plastic injection moulding materials and what they can achieve for your business, get in touch with our helpful team today at +44 (0) 1384 77569 or via email at info@plasticsuppliesdudley.co.uk.

If you found this blog useful, please take a look at a previous one: Energy Waste in the Plastic Injection Moulding Industry