In today’s fast-paced manufacturing world, plastic moulding solutions have emerged as a game changer. With their versatile applications and efficiency, these solutions are revolutionising industries and products alike. Whether you’re a seasoned professional or just starting your journey in manufacturing, understanding the impact of these innovative techniques is crucial to staying ahead.

What are Plastic Moulding Solutions?

Plastic moulding solutions refer to various techniques used to create items by shaping plastic materials. At their core, these methods enable manufacturers to transform raw plastic into finished products with intricate designs and precise dimensions. This versatility is one reason why plastic moulding has become such a cornerstone of modern production processes.

In essence, plastic moulding solutions encompass several techniques, including injection moulding, blow moulding, and extrusion. Each method has unique strengths, making them suitable for different applications. For instance, injection moulding is ideal for producing high volumes of complex shapes, while blow moulding is often used for creating hollow items like bottles. Understanding these distinctions helps manufacturers choose the right process for their specific needs.

Moreover, these solutions provide manufacturers with the ability to innovate continuously. By experimenting with different materials and moulding techniques, industries can produce a wide array of products, from everyday household items to complex automotive parts. This adaptability not only meets consumer demand but also fuels ongoing advancements in manufacturing technology.

The Different Types of Plastic Moulding Techniques

There are several primary techniques in plastic moulding, each of which serves specific purposes in the manufacturing sector. The most common technique, injection moulding, involves injecting molten plastic into a mould, where it cools and solidifies. This method is widely cherished for its efficiency, allowing high production rates without compromising quality.

Another popular technique is extrusion, which is particularly useful for producing continuous lengths of plastic, such as tubing or sheets. During this process, raw plastic pellets are melted and forced through a die to create the desired shape. This versatility in extrusion allows manufacturers to make specialised products tailored to their needs.

Moreover, blow moulding is an essential technique focused on creating hollow plastic containers. This process involves inflating a heated plastic tube within a mould. The expansion of the material allows for the formation of bottles, jugs, and other hollow shapes, which are prevalent in the packaging industry.

Lastly, manufacturers heat thermoplastic sheets and form them into specific shapes using a mould in the thermoforming process. They often use this method to create packaging materials and trays, valuing its flexibility and capacity to produce lightweight products.

Advantages of Using Plastic Moulding Solutions in Manufacturing

Utilising plastic moulding solutions offers numerous advantages to manufacturers, making it a highly preferred choice in various industries. One of the primary benefits is cost-efficiency. The ability to produce large volumes of products quickly and at a lower cost means manufacturers can remain competitive in a fast-evolving marketplace.

Additionally, plastic moulding techniques greatly enhance design flexibility. Unlike traditional manufacturing methods, plastic moulding allows for the creation of complex shapes and configurations that would otherwise be challenging and expensive to achieve. This opens the door for designers and engineers to push the boundaries of creativity in product development.

Another significant advantage is the sustainability aspect. Many plastic moulding solutions utilise recyclable materials, reducing overall waste. This is crucial in today’s eco-conscious environment as it helps companies align with sustainability goals while also meeting consumer demand for greener products.

Moreover, plastic moulding solutions contribute to product durability and lightweight properties. Products made through these methods are often more resistant to corrosion and wear, enhancing their lifespan. As a result, manufacturers can develop high-quality products that stand the test of time, furthering customer satisfaction.

How Plastic Moulding is Redefining Product Design

The impact of plastic moulding solutions on product design is profound, as these techniques allow for newfound creativity and innovation. Manufacturers are continuously redefining their product lines by incorporating intricate designs that were once considered challenging or impractical. The ability to create unique shapes and forms has transformed how products are conceived and brought to market.

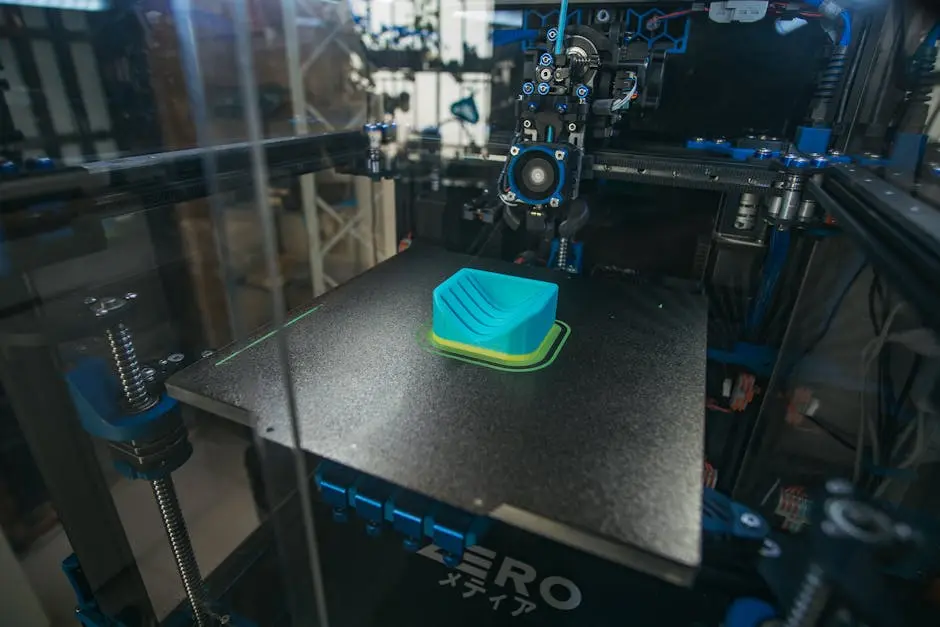

Furthermore, the design process is streamlined through the use of 3D modelling and computer-aided design (CAD). These technologies enable designers to visualise and tweak their concepts digitally before moving to production. This not only accelerates the development timeline but also minimises errors, ensuring that the final product aligns closely with the initial vision.

As a result, designers can experiment with new materials and aesthetics that enhance the end-user experience. Whether it’s developing ergonomic grips for tools or creating intricate patterns on packaging, plastic moulding empowers teams to explore innovative options that captivate consumers.

Sustainability in Plastic Moulding Solutions

Sustainability is becoming a primary concern across all sectors, and plastic moulding solutions are rising to the occasion. Companies are increasingly adopting eco-friendly practices by utilising recycled materials in their production processes. This not only reduces waste but also reinforces a commitment to environmental stewardship, making manufacturers more appealing to conscious consumers.

Additionally, the lightweight nature of plastic products manufactured through moulding techniques means reduced energy consumption during transportation. Lighter products can lead to lower carbon footprints, which is a key factor for many businesses looking to enhance their sustainability efforts.

Moreover, the development of biodegradable plastics is paving the way for even more sustainable solutions. Ongoing research is focused on creating alternatives that maintain the versatility and durability of conventional plastics but with a significantly lesser environmental impact.

Case Studies: Successful Implementation of Plastic Moulding Solutions

Looking at real-life examples helps illuminate the transformative power of plastic moulding solutions in manufacturing. One noteworthy case is that of a global automotive company that adopted injection moulding to produce lightweight components for their vehicles. By streamlining their production line, they not only reduced costs but also improved fuel efficiency in their cars, making a significant impact on the overall sustainability of their offerings.

Another success story comes from the consumer electronics sector, where a company used blow moulding techniques to develop new packaging solutions. By creating robust, lightweight packaging that offered excellent protection, they significantly cut down on material waste while improving the unboxing experience for customers.

These examples underscore the flexibility and adaptability of plastic moulding solutions, proving that investments in these techniques can yield substantial returns in efficiency and innovation.

The Future of Plastic Moulding Solutions in Manufacturing

As we look ahead, the future of plastic moulding solutions appears promising, driven by advancements in technology and an increasing emphasis on sustainability. Developments in automation and robotics will revolutionise production lines, allowing manufacturers to maximise efficiency and minimise labor costs.

Additionally, the continuous evolution of materials used in plastic moulding is opening up new avenues for product development. Innovations in composite plastics, for instance, can enhance durability and reduce environmental impact, setting manufacturing trends that prioritise performance without sacrificing sustainability.

Furthermore, as consumer preferences evolve, manufacturers will need to adapt their product offerings accordingly. This means that those who embrace plastic moulding solutions and invest in research and development to meet emerging demands will likely emerge as industry leaders.

Embracing the Future of Manufacturing with Plastic Moulding Solutions

As we look to the future, it’s clear that plastic moulding solutions will continue to play a vital role in shaping manufacturing. By embracing these technologies, industries can enhance their productivity, reduce costs, and create products that are more sustainable and efficient. The ongoing evolution of these solutions promises a brighter future for manufacturing as a whole.